S30815/EN1.4835/253MA Stainless Steel Seamless Pipe

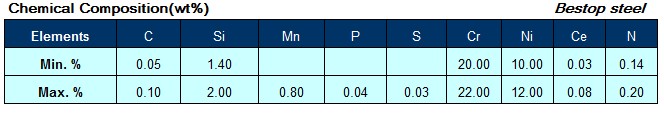

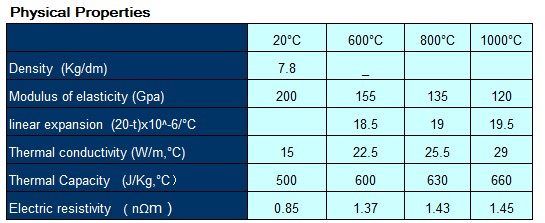

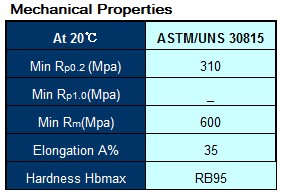

| UNS S30815 (253MA) is an austenitic chromium-nickel steel alloyed with nitrogen and rare earth metals.it produce superior service to TP310,The use of cerium in combination with silicon results in superior oxidation resistance to 2000°F (1093°C). Nitrogen, carbon, and cerium combine to provide creep rupture strength that is double that of type 310 and 309 stainless at 1600°F (871°C).A wide variety of components requiring high strength at elevated temperatures. | |

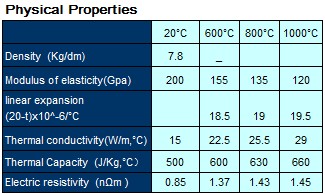

It's classical Features: |

|

|

| Heat treatment |

Description:

UNS S30815 253MA 1.4835 High Strength Heat Resistant Stainless Steel Pipe or Tube

Standard:

ASTM A213, A249,A269, A358,A312, A511, A554, A789, A790, A376, EN 10216-5, EN 10297, EN 10217, EN 10296,DIN 17456, DIN 17458,JISG3459, JIS GS3463, GS3467, JIS G3448, GOST 9940, GOST 9941,

Material: UNS S30815 253Ma 1.4835

Nominal Dia: 1/2 "to 24" NB for seamless pipe, 3/8" to 40" NB for welded pipe

Schedules: 5S, 10S, 40S, 80S, 10, 20, 30...120, 140, 160, XXS

All dimensions are in accordance with ANSI B36.19 and ANSI B36.10

Size Range for tubing: OD:1/4" (6.35mm) to 8" (203mm), WT 0.02" (0.5mm) to 0.5"(12mm)

Length:

15m(Max) or as your requirement

Process:

Cold drawn, Cold rolled, Precision Rolled for Seamless Pipe or Tube

Gas tungsten arc welding, Plasma arc welding (PAW),Submerged arc welding (SAW) For Welded Pipe or Tube

Finish: Annealed & pickled, Bright annealing, polished

Ends: Beveled or plain end, square cut, burr free ,Plastic Cap at Both end

Packing: Bare packing/bundle packing with woven bag/wooden or steel frame crate packing/plastic cap protection at the both sides of tubes and suitably protected for sea-worthly delivery or as requested.

Inspection and Test Procedure

1.100% PMI,Spectro Chemical Aanlysis Test for Raw Material

2.100% Dimension & Visual Examination

3. Mechanical Properties Test Include Tension Test,Flaring Test (For Seamless tube/pipe)/ Flange Test (For Welded Pipe & Tube), Hardness Test ,Reversed Flattening Test

4.100% Hydrostatic Test or 100% NON-DESTRUCTIVE Test (ET or UT)

5.Radiographic Test for Welded Pipe (shall be accordance with specification,or shall be as agreed upon between the purchaser and vendor)

6.Straightness Test (optional)

7.Roughness Test (optional)

8.Intergranular Corrosion Test(optional)

9.Impact Test (optional)

10.Grain Size Determinations (optional)

NOTES : ALL THE TESTS AND INSPECTION RESULT NEED TO BE SHOWED IN REPORTS ACCORDING TO STANDARD AND SPECIFICATION.

Application: | |

| •Injection of pulverized coal in blast furnaces •Fluidized-bed combustion plants •Furnace tubes for mud incineration plants •Carbon black process gas coolers •The glass and cement industries •Styrene reactor tubes •Convection tubes in ethylene cracking |

|

| •Air preheater tubes in sulphuric acid gas convertersTubes in waste heat recovery systems in the metallurgical industry, e.g. recuperators | |

For more information,please connect with us by salse@bstpsteel.com.